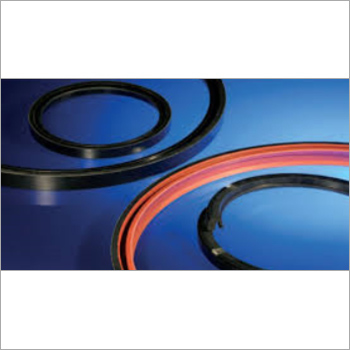

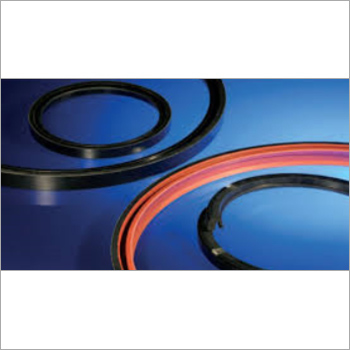

Walker Seal

Product Details:

- Size Different Available

- Color Multicolor

- Usage Industrial

- Material Rubber

- Shape Round

- Hardness Yes

- Click to view more

X

Walker Seal Price And Quantity

- 10 Piece

Walker Seal Product Specifications

- Round

- Multicolor

- Rubber

- Yes

- Industrial

- Different Available

Walker Seal Trade Information

- 100 Piece Per Day

- 8-10 Days

Product Description

<p style="margin-bottom: 0.28cm; line-height: 108%;" align="justify"> We have successfully developed a number of standard metric sizes for various shaft diameters of Walker Radial Lip Seals in M1 material and D6 design. Any other size can also be developed as per customer requirements.</p> <p style="margin-bottom: 0.28cm; line-height: 108%;" align="justify">Walker seals D6 is our highly successful standard design. It is suitable for the vast majority of bearing protection duties and other radial lip seal applications across all sectors of industry.</p> <p style="margin-bottom: 0.28cm; line-height: 108%;" align="justify"><strong>Special features</strong></p> <div align="justify"><ul><li>Lip profile minimises heat generation and shaft wear.</li><li>Geometry gives lip flexibility to accommodate shaft eccentricity.</li><li>Works at up to 20 kPa pressure differential; or up to 200 kPa with lip support plate.</li></ul></div>

FAQs of Walker Seal:

Q: What is the hardness of the Walker Seal?

A: The hardness of the Walker Seal is yes.Q: What is the shape of the Walker Seal?

A: The shape of the Walker Seal is round.Q: What material is the Walker Seal made of?

A: The Walker Seal is made of rubber.Q: What colors are available for the Walker Seal?

A: The Walker Seal is available in multicolor.Q: What is the primary usage of the Walker Seal?

A: The Walker Seal is primarily used in industrial settings.Q: What sizes are available for the Walker Seal?

A: The Walker Seal is available in different sizes.Q: Is the Walker Seal suitable for heavy-duty industrial use?

A: Yes, the Walker Seal is suitable for heavy-duty industrial use.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese Call Me Free

Call Me Free Send SMS

Send SMS Send Inquiry

Send Inquiry