Gate Seals For Hydro Power Plants

1000.0 INR/Piece

Product Details:

- Size 2-3 Inch

- Usage Hydro Power Plants

- Product Type Gate Seals For Hydro Power Plants

- Color Gray

- Material Rubber

- Shape As per customers requirement

- Application For Hydro Power Plants

- Click to view more

X

Gate Seals For Hydro Power Plants Price And Quantity

- 1000.0 INR/Piece

- 1 Piece

Gate Seals For Hydro Power Plants Product Specifications

- Hydro Power Plants

- 2-3 Inch

- Rubber

- As per customers requirement

- For Hydro Power Plants

- Gate Seals For Hydro Power Plants

- Gray

Gate Seals For Hydro Power Plants Trade Information

- kolkata

- A a D ' u e a n f d n c h e q e g a T s p ' v , ' C h c c C i e ( h ] ( C A ) ' C e r a I n , ' C [ a a s h n ' ' , l r A d i v e T ) e ( T r / T ) ' s

- 1000 Piece Per Day

- 10 Days

- Yes

- e p s a i s b g s i h b e r ' S m p l e e d t n a h y e u y c o p s t ] s p [ ' h t d x i b a n a t o a

- Carton Box

- ' u r a f i e n r c r t h A m h A ' s , l m e r e c a s i t ' ' A S r e ' e i d , ' u , a , c s E s a l ' ' n u r o p e d p ' e ] e r a ' i m , s W E o e r n t e ' M t ' ' A C t u a , o ' a ' , ' a A i a o E i N a c [ A t r i ' t r E , l r '

- [ ' i a l I n d A ' l ]

- ISO 9001:2015

Product Description

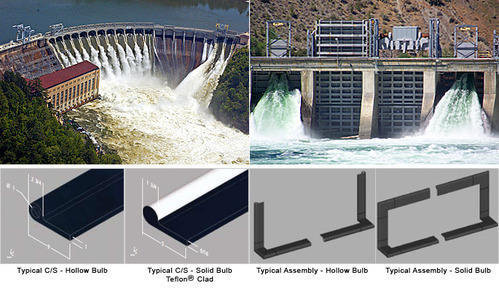

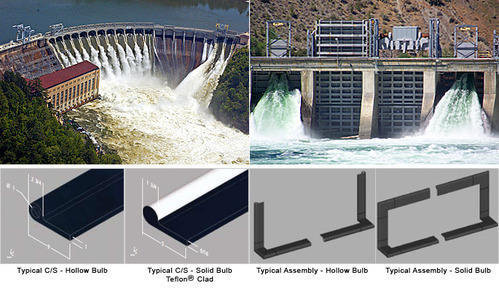

We manufacture a wide range of rubber center-bulb, vertical and companion backstop water stop, music note, hump and flat dam gate seals. These are designed to retain water, prevent water penetration, or limit contaminated run off in civil engineering applications.

The inherent elasticity and resilience of Softex gate seals allow it to retain its sealing effectiveness in situations where there are fluctuating movements caused by water pressure, traffic, subsidence or seismic movement.

Unlike thermoplastic materials such as PVC, rubber seals remain dimensionally stable and functionally effective over many years whilst handling movement far in excess of the capability of PVC. Rubber seals provide superior resistance to chemical attack and heat degradation.

Quality of Softex dam gate seals are very well accepted by various Government and private agencies. We have supplied numerous Gate seals for no. of dams across the world. Our gate seals are also been accepted as Hydrogates in power supply.

Softex produces rubber dam gate seal by moulding method, Quality of which is better than extruded seals. Pressurized curing during moulding ensures close dimensional control, superior physical properties, compact microstructures, thus improved durability and functionality.

We manufacture J Seal/P Seal, Wedge Seal/Flat Seal,Musical Note Seal,Double Bulb Seal, Double Stem Seals etc. as per customer drawings with or without cladding. We also make Corner Seals suitable for the Gate Seal as per client requirements.

We specialize in manufacturing various types of Gate Seals for Hydro power plants & dams with/without

Brass/Teflon/S.S. cladding

Asbestos/Canvas reinforcement with solid /hollow bulb at the centre or at edges.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese Send SMS

Send SMS Send Inquiry

Send Inquiry